Description

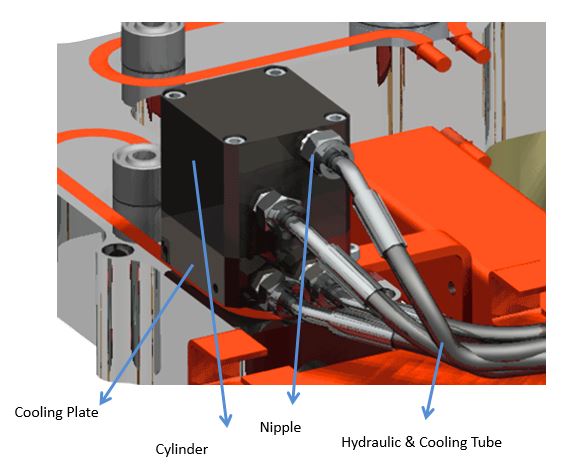

Hydraulic & Cooling Tube

The structure is easy, oil-leaking will not be happened .Cooling plate is set up so as to cool off cylinder and increase the O-Ring’s life span. O-ring max pressure: 315 bar – Using Parker, Oil-leaking can be avoided because that there is inserted O-Ring inside the nipple.

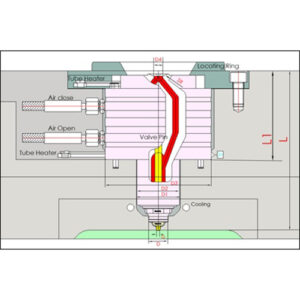

Cooling Plate

Apply Cooling plate under cylinder, to prevent heat conduction from Manifold to Cylinder and keep the more life cycle for O-ring in cylinder. Cooling PGB by plate, to prevent resin leakage between PIN-PGB.

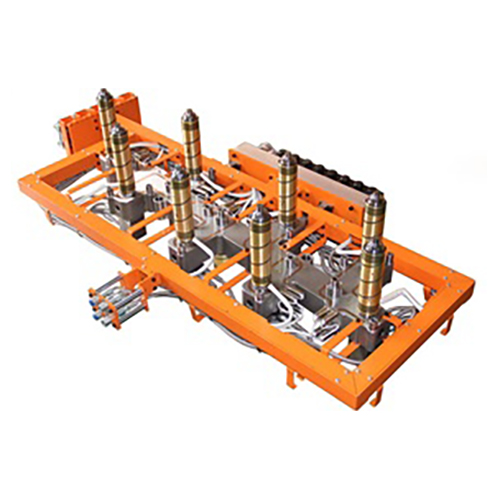

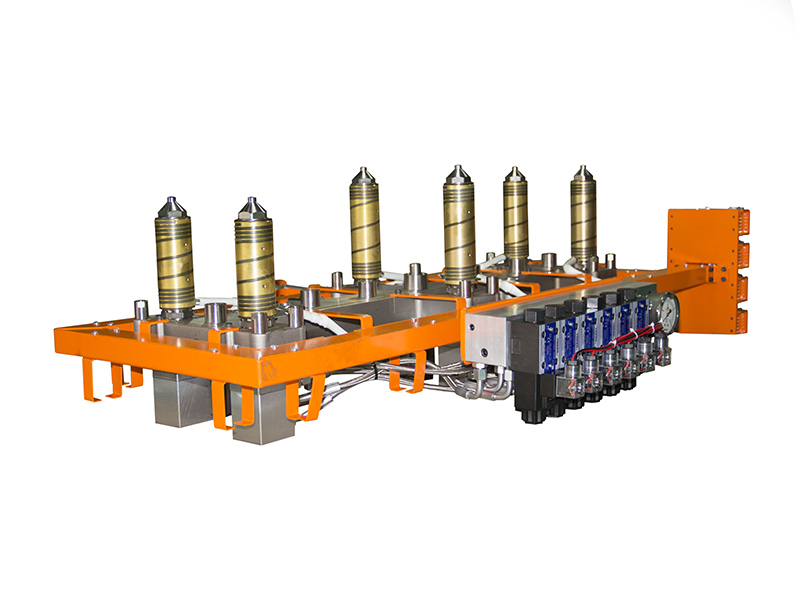

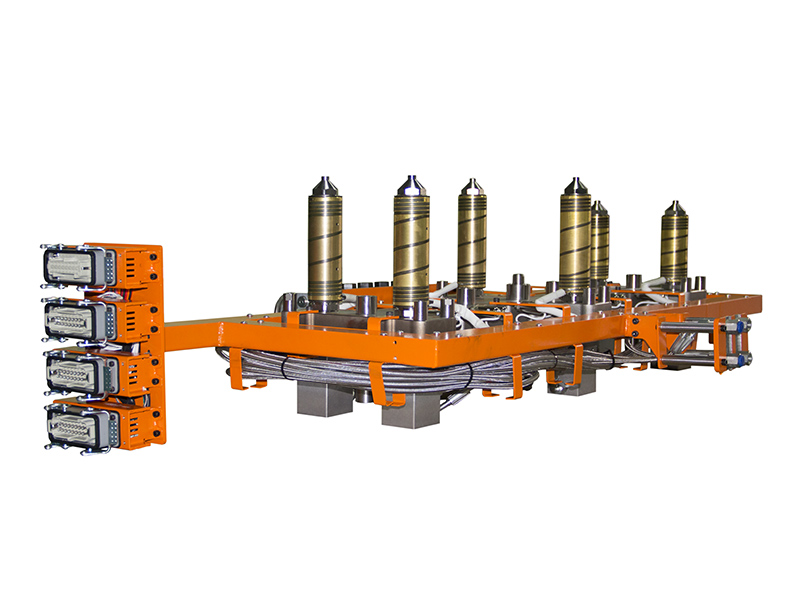

Advantages for Industries using Pre-Wired Integrated Hot Runner Systems

- ➢Easy to Handle the system as assembled system.

- ➢Critical Dimensions and Tolerances are Minimum to manage.

- ➢One man Can Handle the System while Assembly / dismantling from Mold

- ➢Assembly /Dismantling time is very less

- ➢Nozzle are Screwed to avoid Resin Leakages. (mould Break-down time nil)

- ➢Guiding Pin Hole Provision saves the Tips to not get damaged while assembly.

- ➢Easy machining Process .

- ➢Separate duct Protect Wiring form Damages hence increasing there Life Span.

- ➢Gun drilling process in the mold plate is avoided, Pipes and couplers are used for Air and Oil Transfers.

Reviews

There are no reviews yet.